Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Winding tube bobbins have come a long way since their inception, with continuous advancements in technology and materials leading to improved efficiency and versatility. In this article, we will explore some of the recent developments in winding tube bobbin technology and their impact on various industries.

1. Advanced Materials

One of the significant advancements in winding tube bobbins is the use of advanced materials. Traditional materials like plastic, metal, and cardboard have been enhanced to offer improved durability, heat resistance, and eco-friendliness. For example, plastic bobbins now feature reinforced designs, making them more resilient for high-speed applications in the textile industry. Metal bobbins have been engineered to withstand extreme temperatures, expanding their use in demanding industrial processes.

2. Precision Manufacturing

Modern manufacturing techniques have allowed for the production of bobbins with higher precision and consistency. Computer-controlled machinery ensures that bobbins are made to exact specifications, reducing variations and defects. This precision is critical in industries where uniform winding and tension are paramount, such as electronics and wire production.

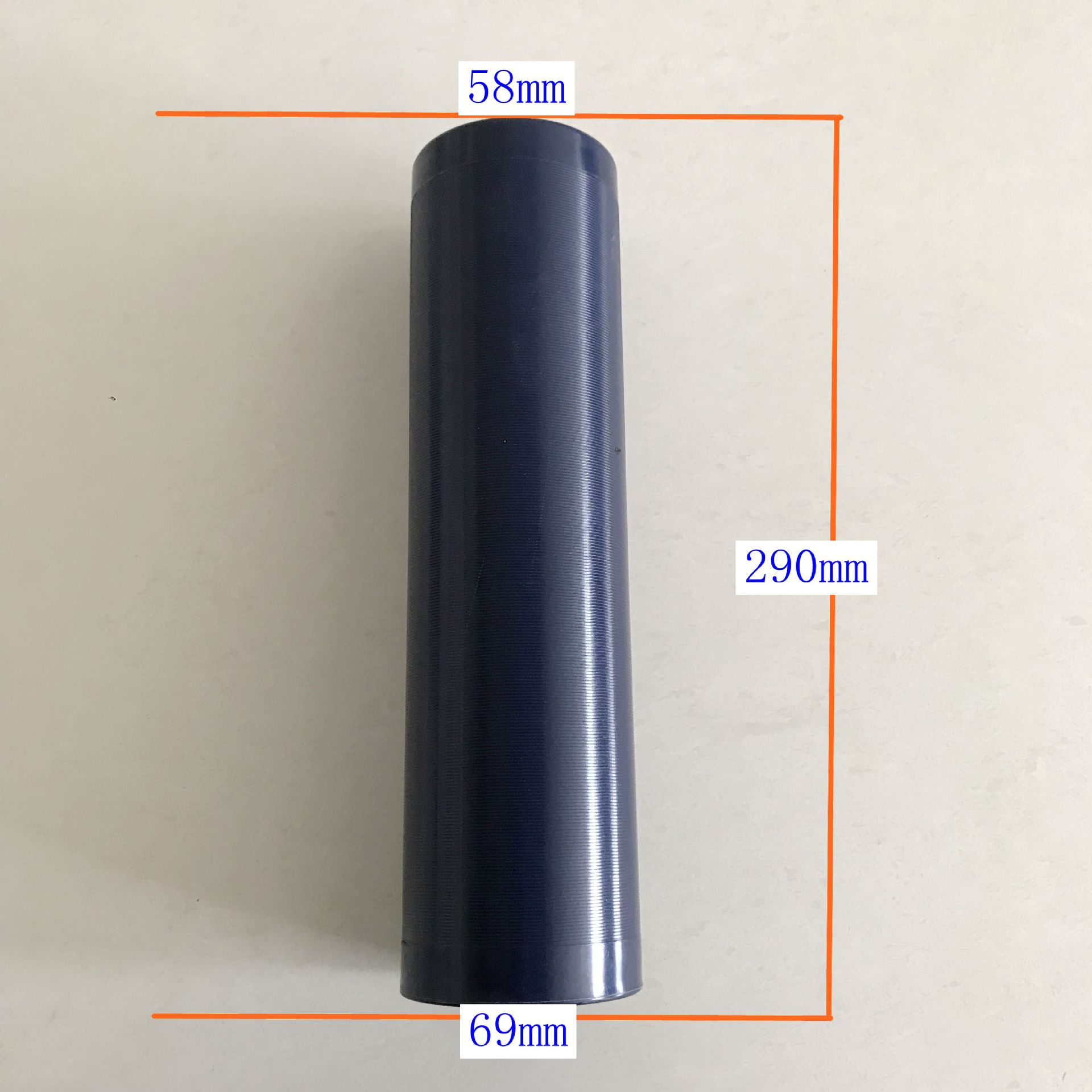

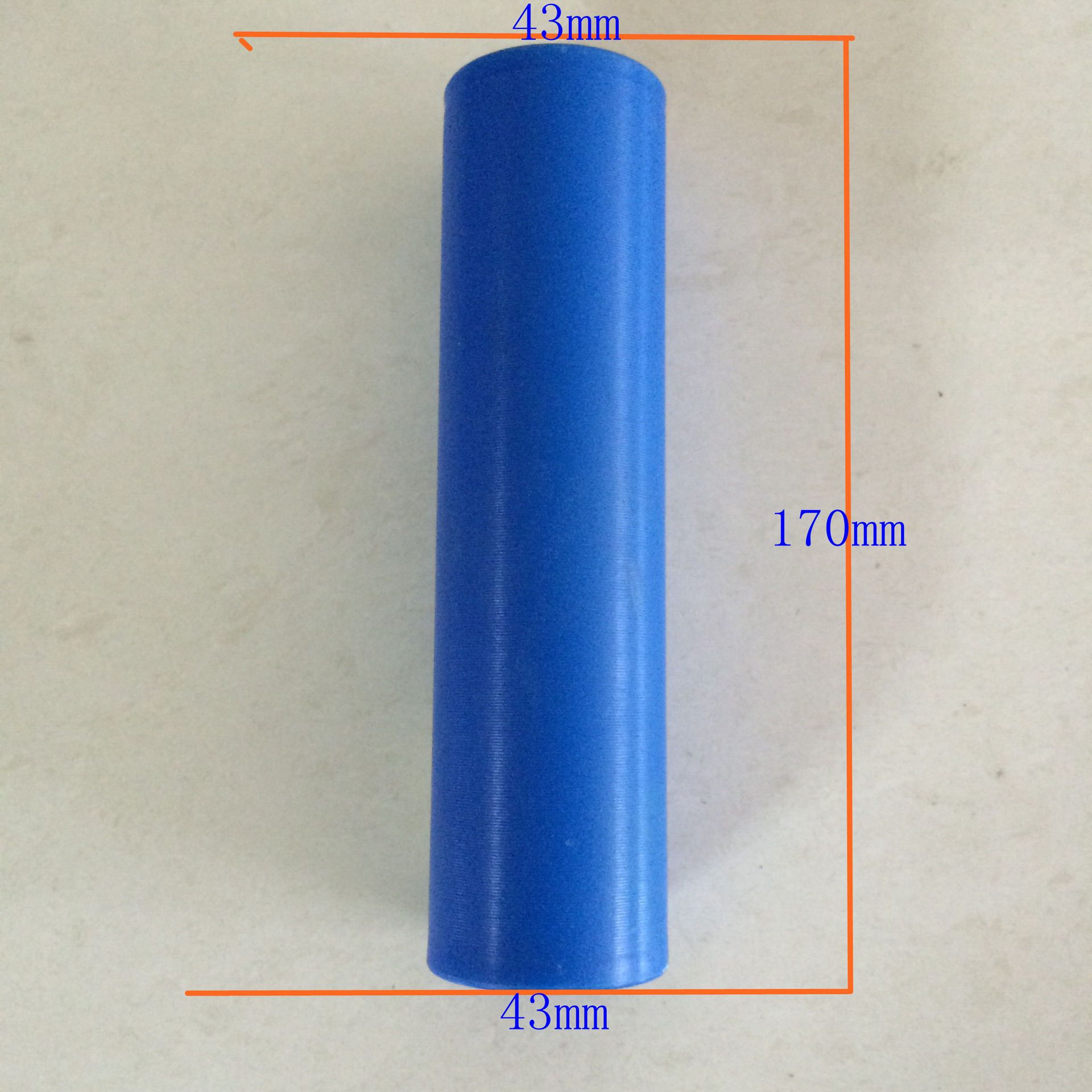

3. Specialized Bobbin Designs

In response to industry-specific needs, specialized bobbin designs have emerged. For example, in the automotive industry, bobbins with unique shapes and features are used for winding electrical cables in vehicles. These specialized bobbins help streamline manufacturing processes and improve the overall quality of the end product.

4. Smart Bobbins

With the advent of the Internet of Things (IoT), some winding tube bobbins now come equipped with sensors and tracking capabilities. These "smart" bobbins can monitor tension, temperature, and other variables during winding and report data in real-time. This technology enables manufacturers to optimize their processes, reduce waste, and predict maintenance needs, ultimately leading to cost savings and improved efficiency.

5. Sustainable Solutions

As sustainability becomes a growing concern, the winding tube bobbin industry has responded with eco-friendly solutions. Manufacturers are exploring biodegradable materials and recycling programs to reduce the environmental impact of bobbins. Cardboard and paper-based bobbins, for instance, are gaining popularity due to their renewable and recyclable nature.

Conclusion

Winding tube bobbins have evolved significantly in recent years, thanks to advancements in materials, manufacturing processes, and technology. These developments have not only improved the efficiency and quality of various industries but have also contributed to more sustainable practices. As technology continues to advance, we can expect further innovations in winding tube bobbin design and functionality, making them even more indispensable in the manufacturing world.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.