Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Spool moulds are essential tools in the manufacturing industry, particularly in the production of various types of wire spools. These moulds play a crucial role in shaping and creating the cylindrical components used to hold wires, cables, threads, and other materials. In this article, we will explore the significance of spool moulds, their applications, and the manufacturing process involved.

Importance of Spool Moulds

Spools are widely used in various industries, including textiles, telecommunications, electrical wiring, and more. They serve as a convenient way to store and dispense materials like wires and threads. To create a spool, manufacturers rely on spool moulds, which allow for precise shaping and consistency in production. Spool moulds are essential because they ensure that the resulting spools have uniform dimensions, which is critical for compatibility with machinery and efficient material handling.

Applications of Spool Moulds

Textile Industry: Spool moulds are extensively used in the textile industry to produce bobbins and spools for threads and yarns. These components are vital for sewing machines and weaving equipment, as they allow for the controlled dispensing of thread during the manufacturing process.

Electrical and Telecommunications: Wire spools created using spool moulds are essential in the electrical and telecommunications sectors. They facilitate the storage and transportation of wires, ensuring they remain untangled and organized.

Fishing and Sports: Spool moulds are also used in the production of fishing reels and sports equipment, such as fishing lines and kite strings. These moulds contribute to the durability and functionality of these products.

Manufacturing Process

The manufacturing process of spool moulds involves several key steps:

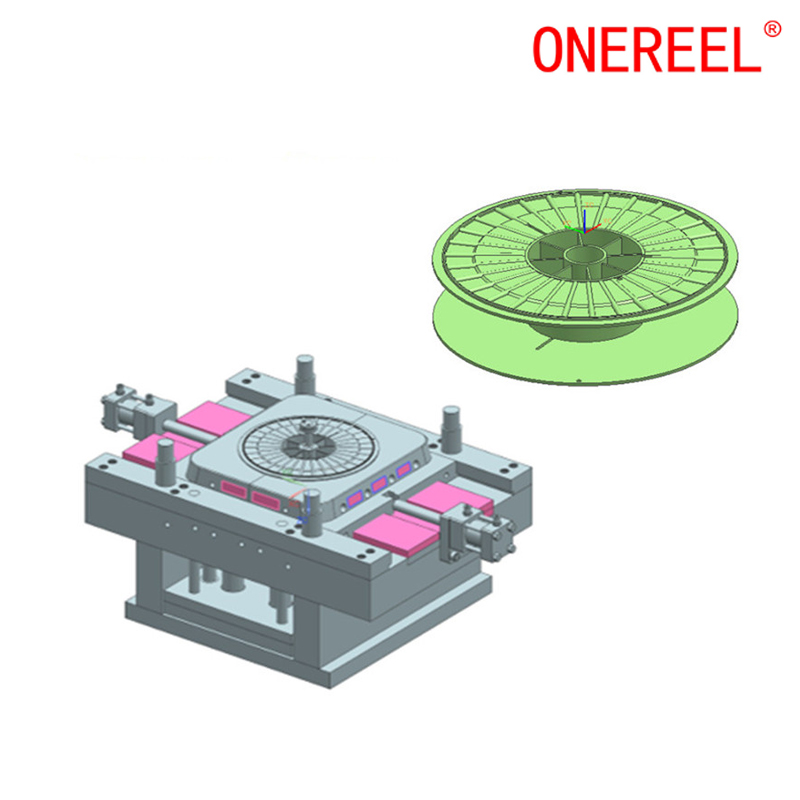

Design: The first step is designing the Spool mould. Engineers use computer-aided design (CAD) software to create precise blueprints that outline the dimensions and specifications of the spool.

Material Selection: Once the design is complete, the next step is selecting the appropriate material for the mould. Common materials include steel and aluminum, chosen for their durability and heat resistance.

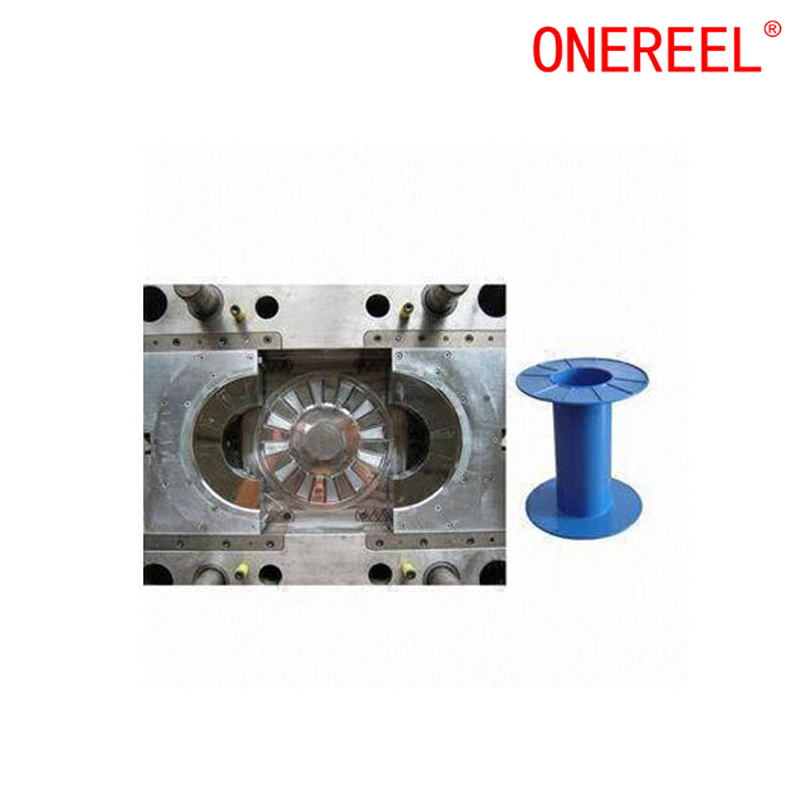

Machining: The selected material is then machined to create the mould's shape. Computer numerical control (CNC) machines are often used for this purpose, ensuring accuracy and consistency.

Heat Treatment: To enhance the hardness and durability of the mould, it undergoes a heat treatment process. This step is crucial to ensure the mould can withstand the pressures and temperatures of the injection moulding process.

Injection Moulding: The mould is mounted in an injection moulding machine, and molten plastic is injected into it. This plastic takes on the shape of the mould and cools to form the final spool.

Finishing and Quality Control: After the spool is removed from the mould, it undergoes finishing processes such as trimming and polishing to achieve the desired surface finish. Quality control measures are implemented to ensure each spool meets the specified standards.

In conclusion, spool moulds are indispensable tools in various industries, ensuring the consistent production of wire and thread spools. Their precision in shaping these cylindrical components contributes to the efficiency and functionality of numerous products. Understanding the importance and manufacturing process of spool moulds provides valuable insights into the world of manufacturing.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.