Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The textile industry has witnessed significant advancements in warp knitting technology in recent years, and one area that has seen noteworthy innovations is the Warp Knitting Beam. These technological developments have enhanced the efficiency, precision, and adaptability of warp knitting machines, allowing manufacturers to create a wider range of fabrics with higher quality. In this article, we will explore some of the key innovations in warp knitting beam technology.

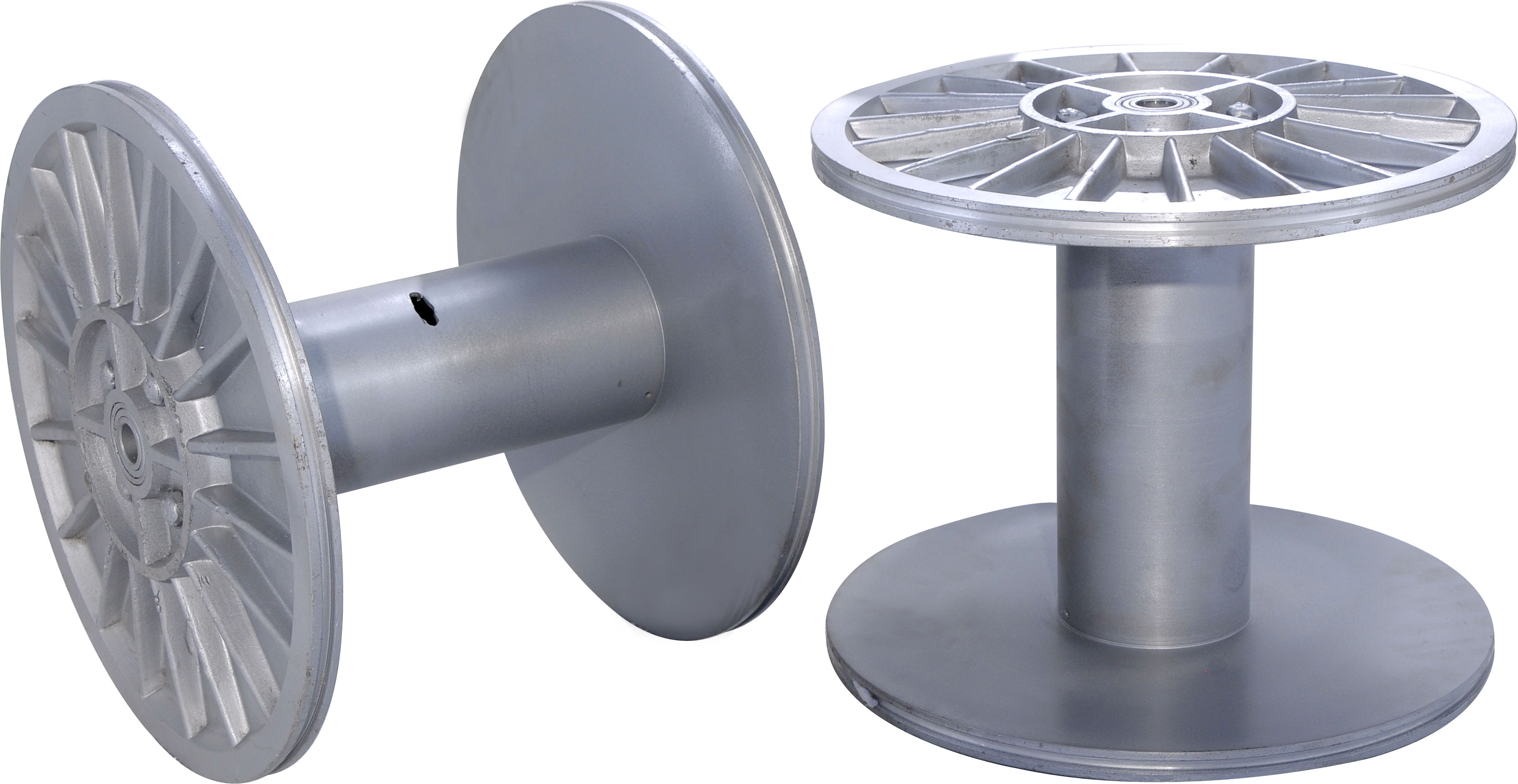

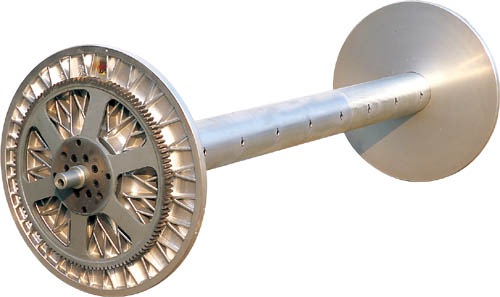

Lightweight Materials: Traditional warp knitting beams were typically made of steel or other heavy materials. However, modern warp knitting beams are often constructed from lightweight materials like carbon fiber or aluminum. This reduction in weight results in less strain on the knitting machine's drive system, improving machine longevity and reducing energy consumption.

Electronic Yarn Tension Control: Precise tension control is vital in warp knitting to produce high-quality fabrics. Advanced warp knitting beams now come equipped with electronic tension sensors and control systems. These systems continuously monitor and adjust the tension of the yarn, reducing the risk of yarn breakage and ensuring uniform fabric quality.

Modular Design: Manufacturers have introduced modular warp knitting beams, allowing for quick and easy changes in the beam's configuration. This innovation enhances the flexibility of the warp knitting machine, making it easier to switch between different yarn types or colors, thereby increasing productivity and reducing downtime.

Improved Yarn Path Geometry: The path that the yarn takes as it unwinds from the warp knitting beam plays a crucial role in determining the fabric's structure and properties. Innovations in warp knitting beam design have led to improved yarn path geometry, resulting in fabrics with enhanced stitch quality and reduced defects.

Beam Creel Systems: Warp knitting machines often use multiple beams simultaneously to create intricate patterns or multicolored fabrics. Beam creel systems have been improved to ensure the precise alignment and tension control of multiple beams, allowing for the creation of complex and highly detailed fabrics.

Automated Beam Loading: In the past, loading yarn onto warp knitting beams was a manual and time-consuming process. However, automated loading systems are now available, reducing labor costs and increasing the overall efficiency of the knitting process.

These innovations in warp knitting beam technology have revolutionized the textile industry, making warp knitting machines more versatile and efficient. Textile manufacturers can now produce a wider range of high-quality fabrics while reducing production costs and environmental impact.

In conclusion, the continuous development and adoption of advanced warp knitting beam technology have propelled the textile industry into a new era of warp knitting efficiency and versatility, opening doors to a plethora of creative possibilities for fabric production.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.