Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

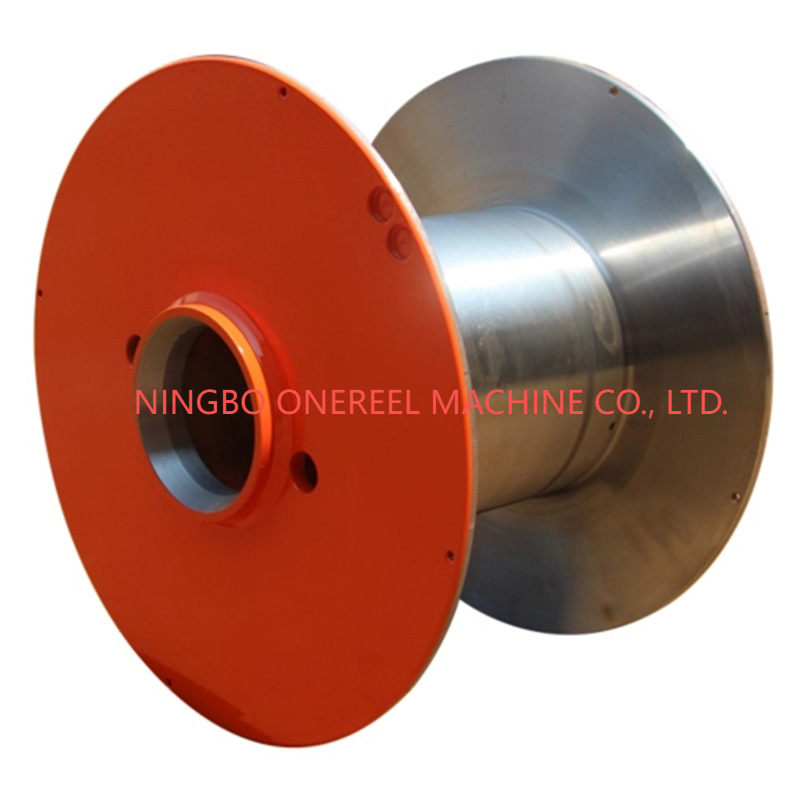

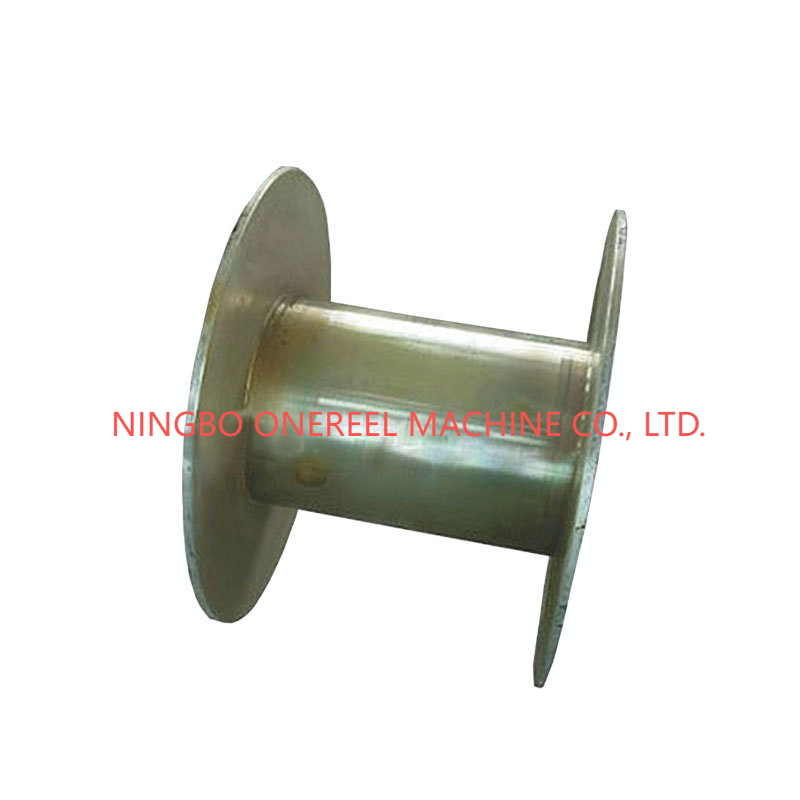

In recent years, advancements in manufacturing technology have revolutionized the production of flat cable reels, leading to improved efficiency, durability, and versatility. Let's explore some of the innovative technologies shaping the manufacturing process of flat cable reels:

1. Additive Manufacturing (3D Printing):

2. Automation and Robotics:

3. Smart Manufacturing Systems:

4. Sustainable Materials and Practices:

5. Customization and Personalization:

In conclusion, innovations in manufacturing technology are driving significant advancements in the production of flat cable reels, enabling manufacturers to deliver higher quality products with greater efficiency and customization options. By leveraging these technologies, manufacturers can stay ahead of the competition and meet the evolving needs of customers in various industries.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.