Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

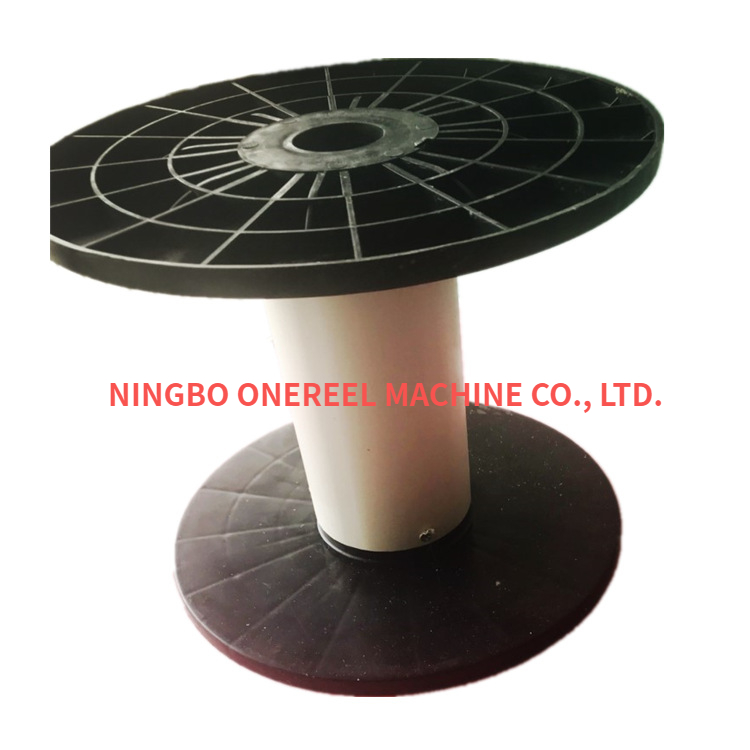

Empty plastic reels have undergone significant evolution over the years, driven by innovations aimed at enhancing efficiency and sustainability in the packaging industry. From traditional spool designs to advanced, eco-friendly solutions, manufacturers continue to push the boundaries of what these cylindrical structures can offer. Here's a glimpse into the evolution of empty plastic reels and the innovations shaping their future:

Lightweight Materials: Early plastic reels were often bulky and heavy, limiting their usability and transportability. However, advancements in material science have led to the development of lightweight plastics without compromising strength and durability. These lightweight reels offer improved handling efficiency and reduced shipping costs, contributing to overall supply chain optimization.

Collapsible Designs: Recognizing the need for space-saving solutions, manufacturers have introduced collapsible plastic reel designs. These reels feature collapsible sides or components that allow for compact storage when not in use. Such designs minimize storage footprint and facilitate efficient return logistics, reducing empty space in warehouses and transportation vehicles.

Biodegradable Options: With growing environmental concerns, there's been a shift towards biodegradable plastic materials in reel manufacturing. These reels are designed to degrade naturally over time, reducing their environmental impact compared to traditional plastics. Biodegradable options offer a sustainable alternative for industries striving to minimize their carbon footprint and embrace eco-friendly practices.

Smart Reel Technology: The integration of smart technologies into plastic reels is revolutionizing packaging processes. Smart reels equipped with RFID tags or IoT sensors enable real-time tracking and monitoring of materials throughout the supply chain. This enhanced visibility enhances inventory management, reduces the risk of loss or theft, and streamlines logistics operations.

Modular and Stackable Designs: Modular and stackable reel designs offer versatility and space efficiency in storage and transportation. These reels feature interlocking mechanisms or modular components that allow for easy stacking, optimizing storage space and simplifying handling. Such designs are particularly beneficial for industries with limited storage capacity or fluctuating inventory levels.

Recycled and Recyclable Materials: Embracing circular economy principles, many manufacturers now produce plastic reels using recycled or recyclable materials. By incorporating post-consumer or post-industrial plastics into their manufacturing processes, these companies reduce reliance on virgin materials and promote closed-loop recycling initiatives. Recycled plastic reels contribute to resource conservation and waste reduction efforts.

In conclusion, the evolution of empty plastic reels reflects a commitment to innovation, efficiency, and sustainability in the packaging industry. From lightweight materials and collapsible designs to biodegradable options and smart technologies, these advancements are reshaping the way materials are spooled, stored, and transported. As manufacturers continue to push the boundaries of what's possible, the future of plastic reels looks increasingly promising in terms of both performance and environmental responsibility.

Tel: 0086-574-86887181

Mobile Phone: +8613777009159

Address: No.1, ChangJiang South Road,Beilun, Ningbo, Zhejiang

Website: https://www.spool-manufacturer.com

Mail: sales@onereel.cn

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.